“More than a buzzword among engineering

millennials?”

A project is a timed initiative. It has a final goal which needs to be completed within a specified time and with specified resources. It starts with a requirement and in the end fulfils that requirement. But in this initiative, anything can go wrong: from work delays to budget overruns, to even getting ‘blocked’.

An improper understanding of all the aspects involved in a project can lead to its premature demise. That is why a proper project management process or project control process must be set up even before project objectives are formed. Project management provides a holistic view of the project along with insights about future, current and past trends in the timeline. This kind of project control system which schedules tasks and offers efficient management of schedules becomes a key factor affecting the progress of projects.

Why Kanban? Every project ever initiated was initiated with a positive mindset about completing it accurately and on time but over the years engineering projects have become increasingly complex, sizeable, and harder to manage, which makes managing the schedules and tasks inevitably cumbersome. Software systems like ERPs are employed to manage large projects and a recent trend in this is the Kanban System. Kanban has become one of the buzzwords among engineering millennials, predominantly in software development projects, but what exactly lies behind this awe-inspiring word?

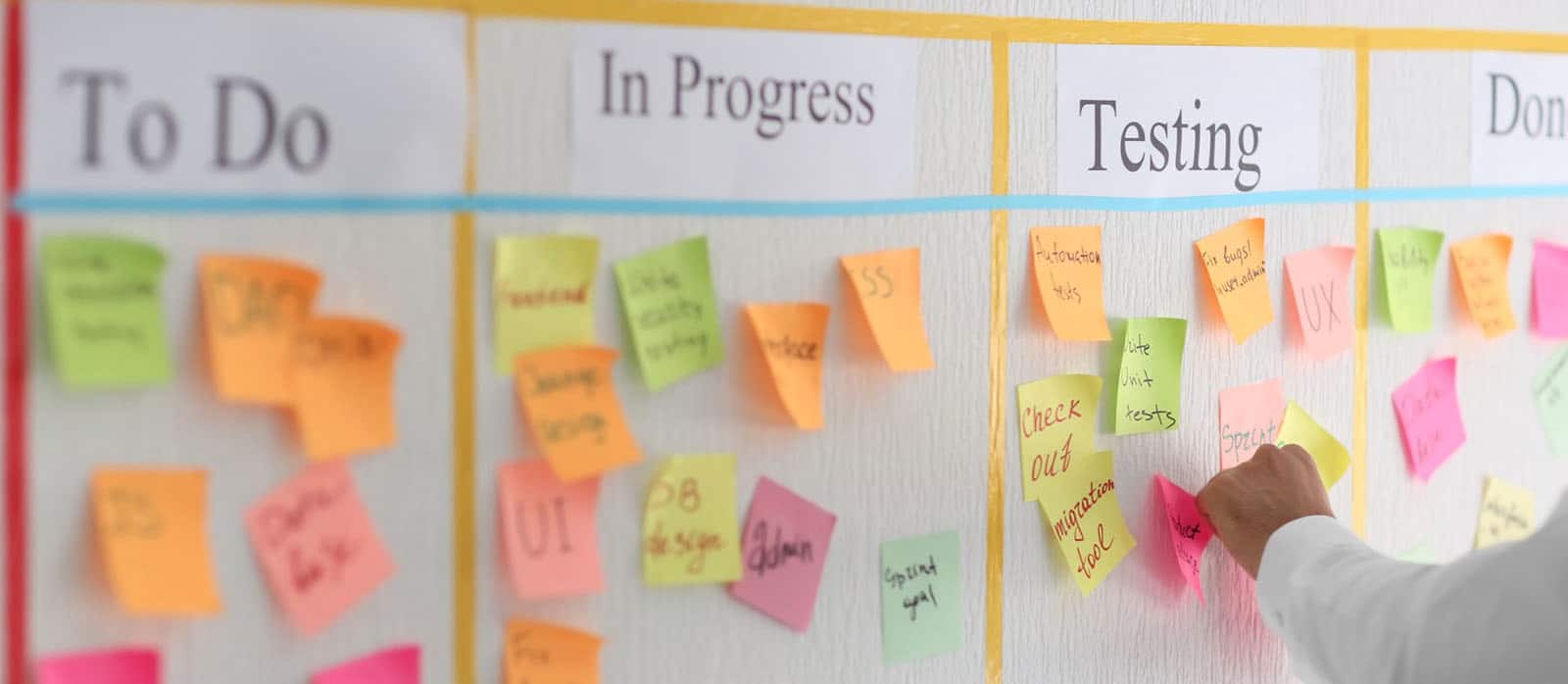

Kanban at a glance: The Kanban system encompasses the simplicity of organizing tasks, called cards, and stacking them to boards (refer image). The boards are further divided into lanes which represent Current, Complete, and Work-in-Progress tasks. As a task moves in, teams can start working on them and the card moves to the Work-in-Progress lane. Once the work is complete the card will move on to the Completed lane. This provides a visual cue to the project manager as well as the teams working collaboratively on the project. The tasks are unitary and as new cards come in they get moved to respective lanes according to their status.

What makes Kanban effective? A key aspect of the Kanban system is the constraint imposed in each work lane. Suppose that, as per the system, the Work-in-Progress lane can hold only 4 cards concurrently. In such a scenario, once 4 cards are in Work-in-Progress no further cards can be taken in. So, this is a type of visual control because the project manager will immediately know to employ more resources into current tasks for completion on time, and as the cards keep moving he can know the overview of each job and its current progress. Such features make the Kanban system very efficient and yet quite simple.

Kanban in large projects: Large projects require many people to work on it. Without a good project control system i.e. the ability to leverage the power of collaboration and team management, it becomes difficult to execute such projects. Here the Kanban system comes into play by ensuring that teams remain consistently on the same page and are able to manage facets that require fast and accurate output.

What’s next for Kanban? The Kanban system was first developed to manage production lines and as we moved away from physical boards it evolved into E-Kanban (used to manage DevOps software development projects). Today the scope of extending and implementing Kanban into other engineering areas is still open, and as the EPC sector gets more and more digitized we can expect to see more such innovations across engineering and project control, which can only be good for the sector.