- Project Management

- 16 Mar 2021

From Reactive to Pro-active Project Management in Engineering Procurement Construction Industry

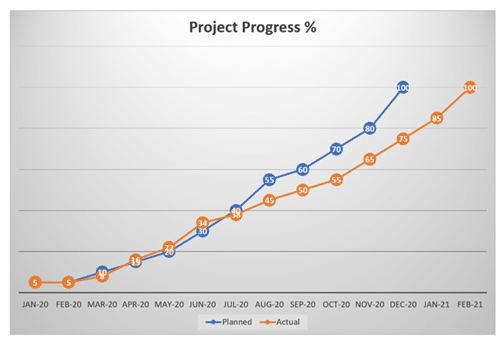

The degree of proactiveness determines the quality of project management. If the project managers spend more time in preventing problems than correcting them, we know that they are practicing proactive project management. Unfortunately, many project managers do not have real-time project progress information on time. Many of them have to wait for at least a week, if not weeks before they get current project progress information. When they finally get it, there is the question of accuracy and relevance. This limits their ability to perform proactive project management.

Proactive project management is very much essential in industries like Engineering Procurement Construction (EPC) , which involves a large sum of money and a lengthy project life cycle.

How can an EPC project move from reactive to proactive project management?

| Reactive progress monitoring | On time progress monitoring | Proactive progress monitoring |

| 1) Long wait for status 2) Inaccurate progress information 3) Information overflow 4) Delay in corrective action 5) Slippages and overruns | 1) Almost real-time status updates 2) Accurate progress information 3) Just in time corrective actions 4) Reduction in slippages and cost overruns | 1) Forecasting of potential overruns 2) Preventing overruns, before they occur |

What are the obstacles in achieving Pro-active project management in EPC industry?

Here are the key reasons;

- Monitoring is done only at the milestone level in EPC projects. Since the time gap between milestones is large, one has to wait for a long time (weeks to months) in order to understand whether the milestone is met or will be met on time.

- Deliverables are not linked to project milestones; hence actual status has to be updated manually.

- Capture of deliverable progress even if done is subjective because of a lack of clarity about the basis for progress updates.

- Manual updating of deliverable progress on a daily basis is tedious – Progress information is to be captured every day to provide enough time to take preventive action. This is tedious if progress is to be updated manually every day.

No proper definition of role up progress hence progress of package or project is not known

How can we switch to proactive project management in the engineering procurement construction industry?

- Automatic update of milestone status from the deliverable status. The milestone status should be aggregated by the roll-up of the deliverable level progress. Steps 2&3 explain this further.

- Roll-up weightage must be defined during the planning stage of the EPC project so that during execution time bottom-up progress rollup can be easily done. This can be achieved by defining the contribution percentage of the lower levels in the WBS to the immediately higher level in the WBS.

- Deliverable workflow process weightage definition and linking them to the corresponding key milestone. This will enable monitoring of the progress of deliverables and the associated milestones. The key steps are;

- Define the workflow of the deliverables

- Define the rules of credit for each stage within the work flow

- Automate the work flow

- Monitor the actual progress automatically as the activity completes the workflow.

- Automatic display of progress delay and notify to concerned to take preventive and corrective action.

- Continuous monitoring – Continuously monitoring the progress delay and taking steps like crashing, fast tracking, etc to correct the delays as soon as possible.

- Forecasting – From the automated real-time progress information, the expected date of completion of the key deliverables, milestones, and also the project can be forecasted frequently. This will truly empower the shift from reactive project management to proactive project management in EPC projects.

Key benefits of proactive project management reported from an Engineering Procurement Construction industry project

- 85% improvement in project management efficiency

- 75% less time in reporting

- 100% quality achievement

- 80% reduction in deliverable management time

- Reduction in review cycle time from 7days to 1 day

Varghese Daniel is the co-founder and CEO of Wrench Solutions. Abrachan Pudussery is domain expert in Project Management area and a seasoned trainer. He heads the Wrench Academy, and brings in deep domain expertise and a conviction about higher quality in project management training.

Related Posts

AI for EPC Project Management: Demystifying Common Myths

AI is being aggressively rolled out in a wide range of industries from Healthcare to Banking to Retail, but the EPC sector seems reluctant to join in. That reluctance, in many cases, stems from widely…

- 20 Feb 2025

How to Select a PMIS for Your Organisation

The modern Project Management Information System (PMIS) is a widely-tested and amply-proven product, having been used on global construction and engineering project management for a long time now. In EPC (Engineering, Procurement, and Construction) projects…

- 29 Nov 2024

Archives

- March 2025

- February 2025

- January 2025

- November 2024

- October 2024

- September 2024

- August 2024

- July 2024

- June 2024

- May 2024

- April 2024

- March 2024

- January 2024

- December 2023

- November 2023

- September 2023

- August 2023

- July 2023

- June 2023

- May 2023

- April 2023

- March 2023

- February 2023

- January 2023

- December 2022

- November 2022

- September 2022

- June 2022

- May 2022

- April 2022

- March 2022

- January 2022

- November 2021

- October 2021

- July 2021

- June 2021

- May 2021

- March 2021

- February 2021

- January 2021

- December 2020

- November 2020

- September 2020

- August 2020

- June 2020

- April 2020

- March 2020

- February 2020

- January 2020

- November 2019

- October 2019

- September 2019

- August 2019

- April 2019

- March 2019

- December 2018

- October 2018

- September 2018

- August 2018

- July 2018

- June 2018

- May 2018

- April 2018

- January 2018

- November 2017

- October 2017

- September 2017

- May 2017

- April 2017

- March 2017

- February 2017

- January 2017